Versatile, FE Based Brush-Commutated Motor Design Tool

BCPM

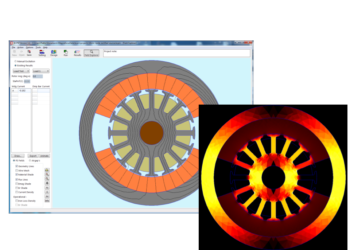

BCPM is a Finite Element Based motor design environment for brush commutated motors. Series, parallel, universal and PM designs are all included within this simulator.

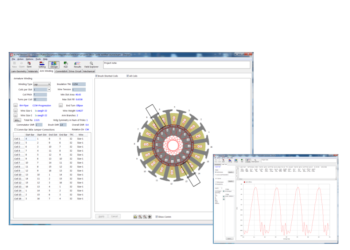

The process begins by choosing from an extensive library of parameterized motor cross sectional modules or by drawing from scratch. Once the geometry is set, the materials are selected and the armature winding is described in a simple table. Windings can be lap or wave with right or left hand progression. Next, the commutator is described in real world, physical terms. Placement of the commutator vis a vie, the windings and the brushes is displayed graphically so the user can ensure proper alignment. Using BCPM’s built-in schematic capture the designer next connects the machine windings and the drive circuitry. The motor is then “run” at a series of user specified load points. The motor system solution is based on the magnetic parameters calculated via a fully automated Finite Element process, including a detailed brush commutation model. Parameterized output is provided without any additional processing. Output ranges from machine currents, voltages, torques, input and output power, efficiency, as well as flux density and demagnetization plots.

- Extensive geometry library

- Ability to add parameterized designs

- PM or wound field topologies included

- Graphical representation of commutator alignment

- Sophisticated communication and arcing models increase precision

- Lumped parameter estimation of brush commutation quality

- Full time domain waveforms of all motor currents including commutation

- Validated with small power tool motors and large DC machines

- Inter-pole and compensation coil support for large motors

- Works with Batch processing for What-if analysis and parametric sweeps

Contact Us

Please feel free to reach out if you have any additional questions about MagneForce Software Systems Inc.